The combination of artificial intelligence, humanoid robotics, and digital twins is revolutionizing the world of work. This transformation is being driven by innovative startups like Robots for Humanity, a company based in Córdoba, Argentina, that aims to accelerate automation in industrial sectors using cutting-edge technologies.

The Potential of Automation

According to Robots for Humanity, nearly 50% of the global GDP, equivalent to around USD 42 trillion, is generated from manual labor that could be automated with advanced humanoid robots. As this technology continues to evolve, labor costs will decrease, making automation a strategic necessity for industries facing complex challenges.

Virtual Environments and Digital Twins

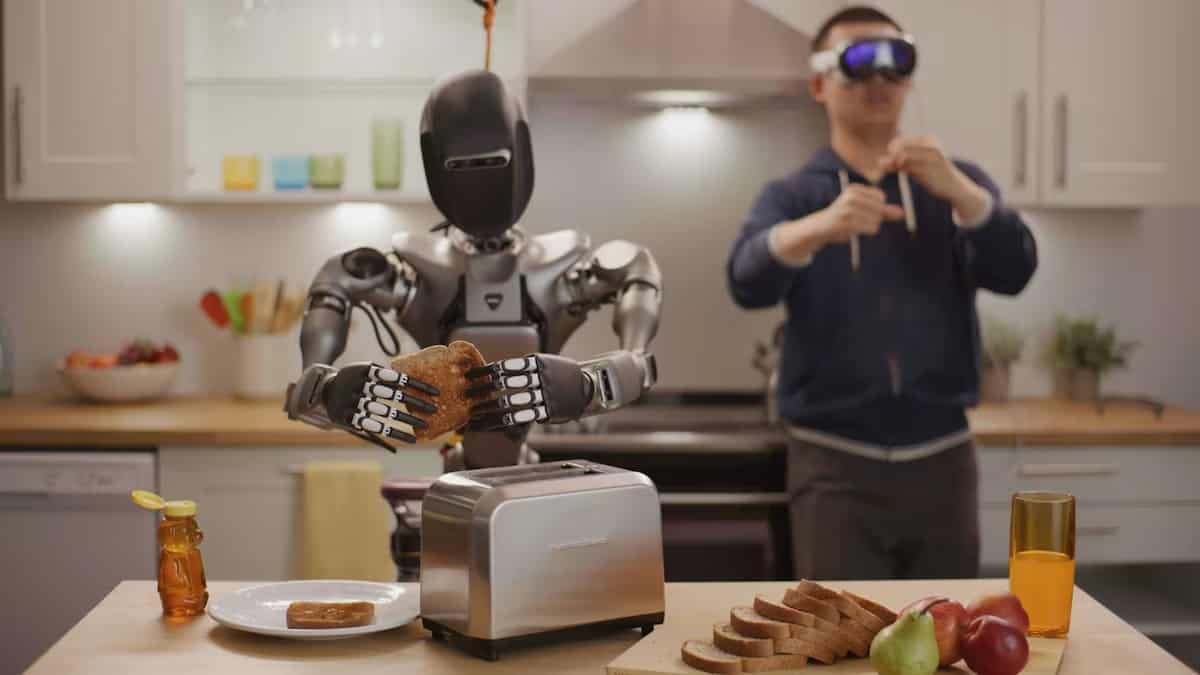

Alejandro Parise, founder of Robots for Humanity, explained that the company starts by creating hyper-realistic digital twins using the Nvidia Omniverse platform. These virtual environments accurately replicate industrial spaces, allowing simulations, training, and performance optimization of robots before their physical deployment.

By leveraging these digital twins, companies can minimize errors, reduce downtime, and ensure seamless integration with existing infrastructure. Once trained in the virtual environment, the robots are deployed in real-world settings. These robots are designed to operate in shared spaces with humans without requiring modifications. They feature 360-degree vision, 20-hour autonomy, and millimeter-level precision, making them ideal for sectors such as automotive manufacturing and oil & gas.

Real-Time Learning and AI Integration

Parise emphasized that these robots collect real-time data to improve their performance through AI algorithms. As they operate, they learn and adapt to their environment, enhancing their ability to perform complex tasks with greater precision and efficiency.

Expansion Plans and Costs

Robots for Humanity currently operates in Córdoba and Buenos Aires and is rapidly expanding. The company plans to deploy ten robots in local industries within the first half of the year and increase that number to 20-30 by year-end. To support this expansion, Parise will travel to China to procure equipment, including models like Unitree G01 and Figure 02.

Robot costs vary depending on the model and application. A basic humanoid robot costs around USD 30,000, while advanced models can reach USD 120,000. Robotic dogs, used for specific tasks like gas leak detection, start at USD 5,000.

Strategic Partnerships and Use Cases

Although specific details remain confidential, Robots for Humanity is in negotiations with various companies to implement its technology in industries such as manufacturing, logistics, and automotive. Humanoid robots are being explored for tasks ranging from assembling components to transporting materials within factories.

A notable case involves integrating these robots into the healthcare sector. Hospitals are testing them for medical supply transportation, assisting patients with limited mobility, and disinfecting sensitive areas. These robots handle repetitive tasks and minimize infection risks in medical environments, allowing healthcare staff to focus on patient care.

The Future of Industry

Robots for Humanity’s vision is not to replace human workers but to complement their tasks and take on dangerous, repetitive, or physically demanding jobs. Parise envisions a future where technology enhances human potential rather than replacing it. He imagines a world where hazardous and exhausting manual labor becomes optional, and industries operate with greater safety, efficiency, and precision through intelligent automation.

To ensure successful implementation, the company defines key performance indicators (KPIs) to measure robot efficiency, operational time, and cost savings. Additionally, they provide preventive and corrective maintenance to maximize the lifespan of their equipment.

Global Trends and Challenges

The growth of humanoid robot automation is not limited to Argentina. In countries like the United States, Japan, and China, tech giants such as Tesla, Boston Dynamics, and Xiaomi are developing increasingly sophisticated robotic models.

The integration of generative AI allows these robots to better understand their environment and perform tasks with greater autonomy. However, widespread adoption faces significant challenges. One of the main concerns is social acceptance and its impact on employment. While experts argue that automation will create new job opportunities in robot supervision, programming, and maintenance, there is apprehension about the retraining of displaced workers.

Another key challenge is the initial implementation cost, particularly for small and medium-sized enterprises (SMEs). The technology remains expensive and requires adequate infrastructure for effective integration. Financing models, tax incentives, and training programs will be crucial for making automation accessible to more industries.

The fusion of AI, humanoid robotics, and digital twins is redefining the landscape of work. While challenges exist, the benefits of increased efficiency, safety, and productivity are undeniable. Companies like Robots for Humanity are at the forefront of this revolution, demonstrating that intelligent automation is not just a possibility but a necessity for the future of industry.